- cross-posted to:

- 3dprinting@lemmy.world

- cross-posted to:

- 3dprinting@lemmy.world

UTILI-SONG evolved into…

…ROCKHOPPER! (Screeaw!)

Printables link: here.

“But you already designed a balisong,” you say. Yes, I did. And it is further said that the definition of insanity is doing the same thing again and expecting a different result.

So I did the same thing again, and I got a different result.

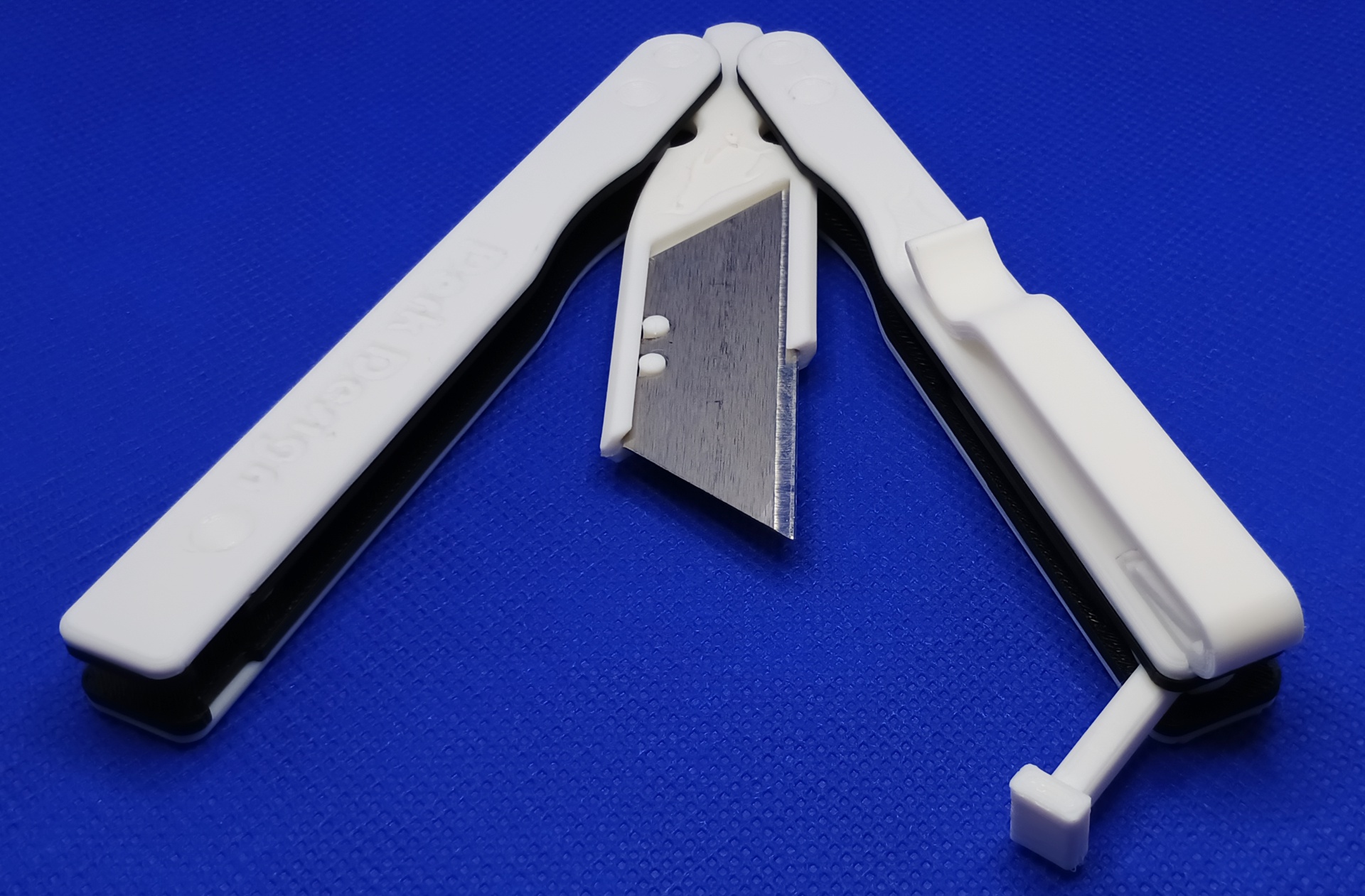

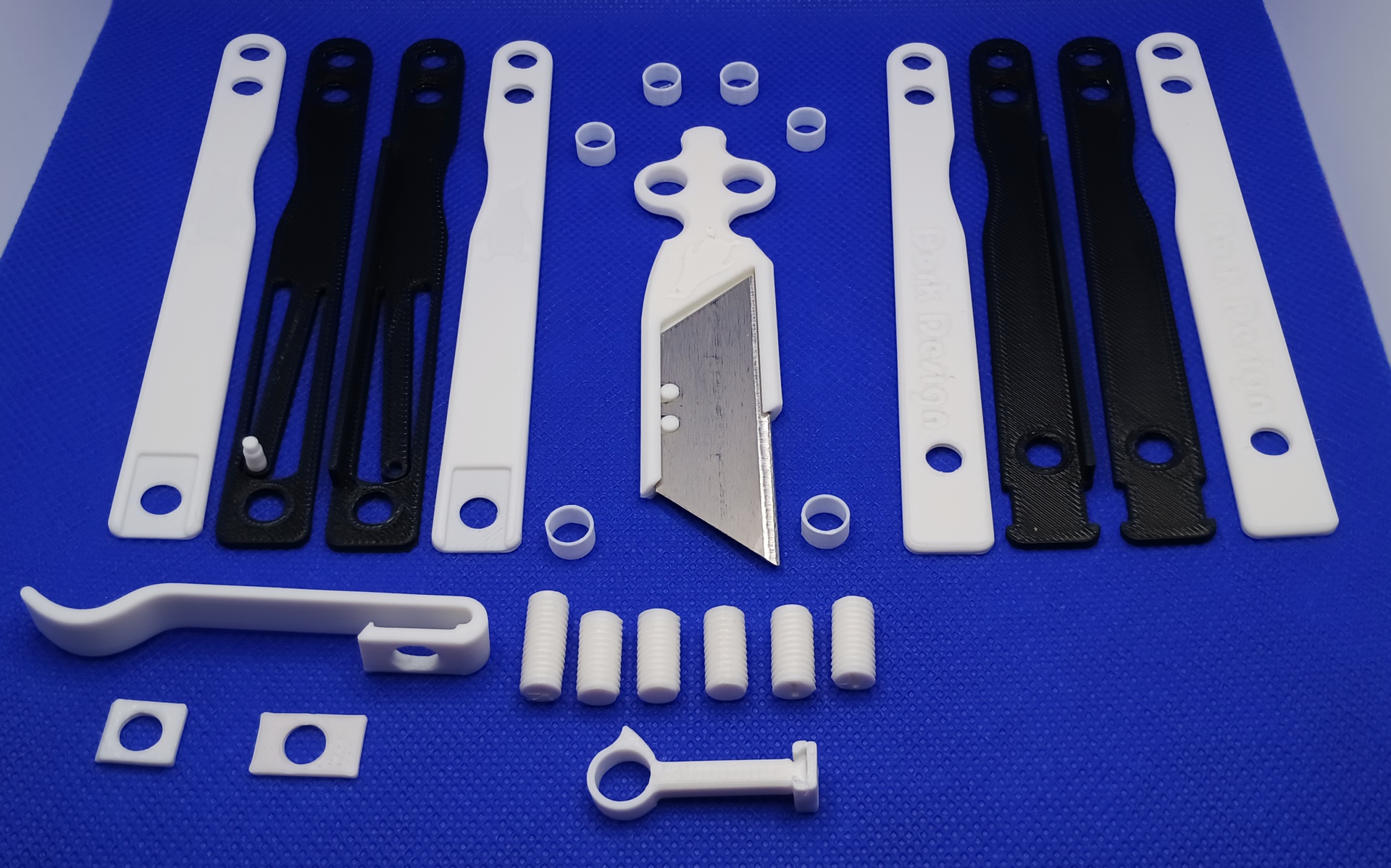

Iteration after iteration, tune after tune, ultimately literally every single component of the original Harrier Utili-Song wound up being changed or in some cases, just outright thrown away and designed anew. This carried on to the extent that I eventually realized we were deep into in a Ship of Theseus situation, and at that point it ought to get a new name. Thus, the Rockhopper was born. So here’s another black and white knife coming at you from the deep blue sea.

It is not an optical illusion, but the handles are subtly tapered which was an important aspect I realized was originally missing. There are also ergonomic finger rest cutouts, which also provide a tactile indication of which side of the handle you’re holding.

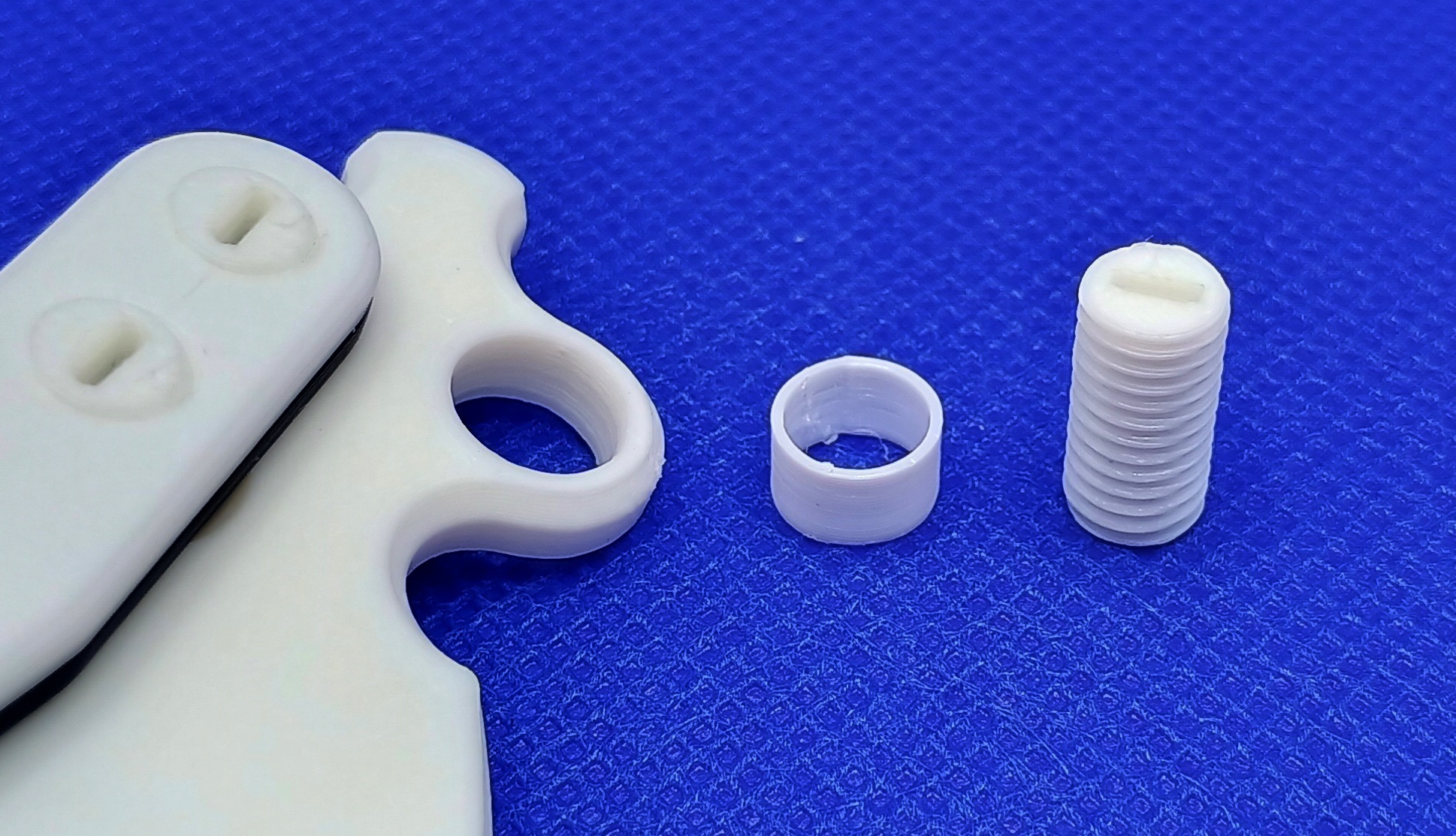

At is core are the headless “Impossible” screws I used on the Adélie design. I liked these so much that I said at the time I would backport the design to my other knives, and here we are.

The next logical step is, of course, to give the Rockhopper bushing pivots to ensure a guaranteed kick-ass action.

And isn’t it just. (Slow mo version here. Warning: That file is 28 megabytes. Sorry, instance admins.)

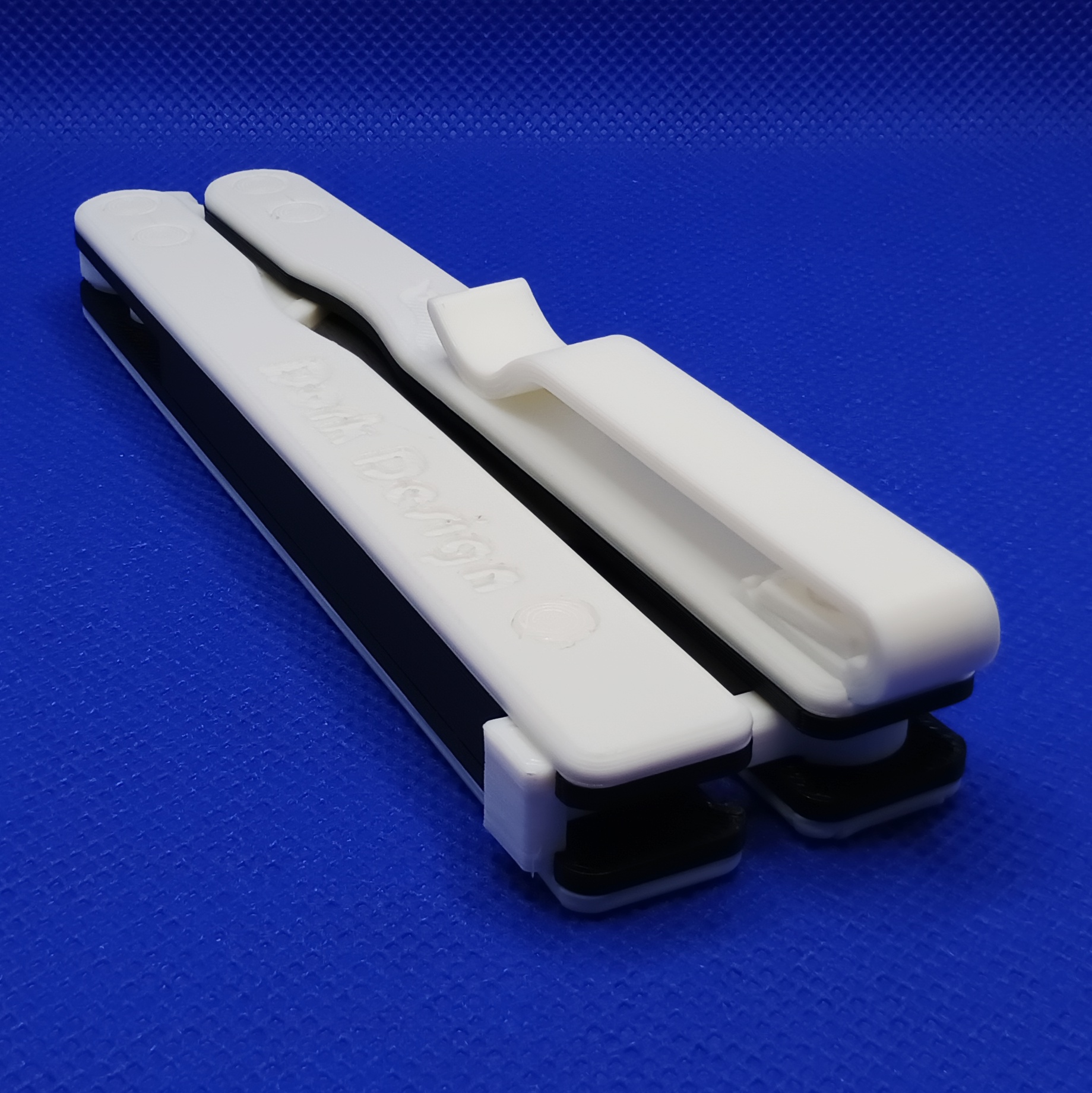

The Rockhopper also has a deep carry pocket clip. I can’t think of any production balisong that does. Maybe there’s one out there but I’m drawing a blank. Give me an “acktshully” in the comments if I’m wrong.

Oh, yeah.

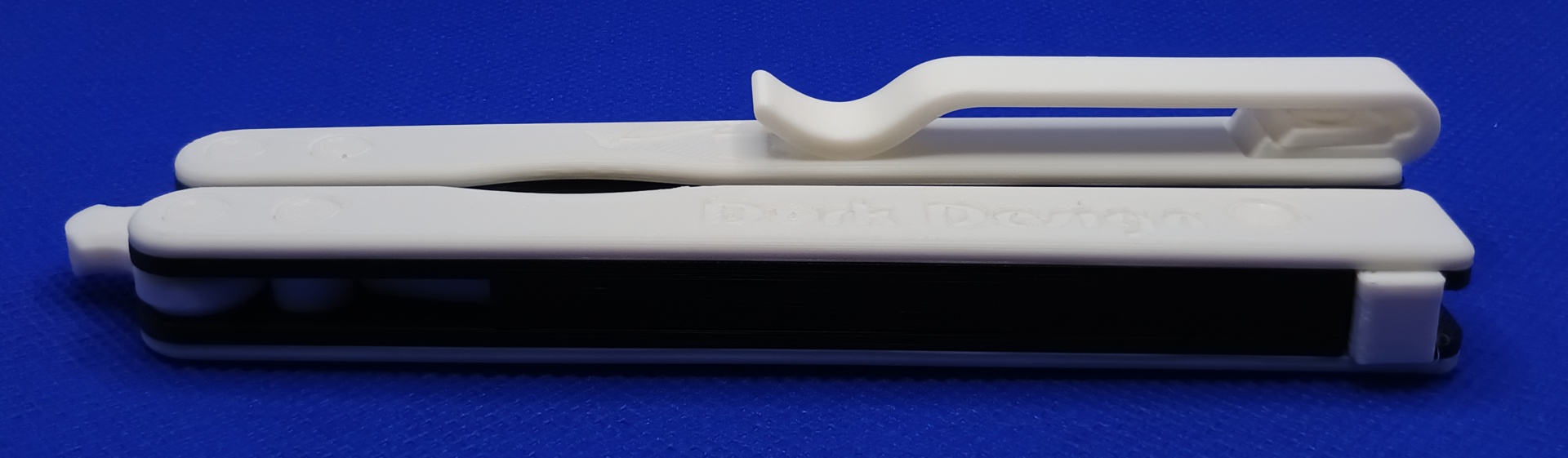

I also added a Morpho style spring loaded squeeze-to-release latch. The latch head is a new lower profile design, and positively locks in place in both the open and closed configurations unless the handles are squeezed.

I could sit there and do that all day.

The spring latch was what gave me the most trouble. Getting that tuned to work reliably was a major chore, and ultimately revealed that you can’t print that component in ordinary PLA if you expect it to work, at least beyond demonstration purposes. Cold creep will eventually do you in if you try, and by “eventually” I actually mean “within a couple of hours of leaving it latched.” Which is a real drag.

But if you print the liners in ABS instead there’s enough creep resistance in the material to make it possible. ABS will also take a minor set after a while, but its permanent deflection is more limited and at least so far in my testing a pair of ABS liners has kept the spring latch perfectly functional from the start right up until the time of writing.

The entire knife has been slimmed down, especially the blade holder, because it turned out the added thickness was actually unnecessary for function and durability. The thinner design feels much nicer in the hand.

And when I said I did a lot of tuning, believe me when I say I was not fucking around.

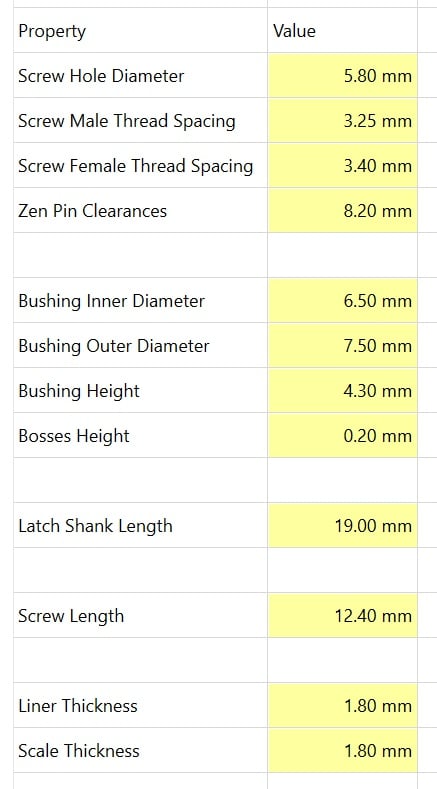

Practically every mechanical aspect is parameterized and configurable, which was necessary to dial in everything to be just so.

That’s because, and I knew this already, designing a balisong knife is actually unexpectedly difficult and complicated. It doesn’t seem like it should be at first blush. I mean, per-industrial Filipino fishermen carved working examples out of whalebone and bamboo or whatever the fuck, right? How hard can it be?

The answer is, very. Making a bali- that spins and goes “clack” is not actually terribly involved. But doing so in a manner that doesn’t suck, works reliably every time, and most importantly can be cranked out on a consumer level 3D printer turned out to be quite involved.

Everything is a factor. Everything. The spacing between the cutouts for the Zen pins, and their diameters. Length of the handles. Angle of taper. Length of the latch, to compensate for angle of taper. Clearances between the bushings, the screws, and the blade. Height of the pivot bosses. Interface between the tang and the pins. Everything works in concert with everything else.

If you’ve ever wondered why Chinese flea market balisongs are such crap, this is exactly why. All of that stuff has to be right, and it has to be consistent, and that’s not easy.

I designed the Rockhopper to be an intermediate sized knife. It’s 4-15/16" long closed, not including the protrusion to the rear from the clip. Open and latched it’s 7-5/8" long, including the length of a typical Stanley style utility knife blade. It’s 11.5mm thick or 0.45" in total, again without the clip. And printed with 100% infill in a combination of PLA and ABS, it weighs 36.1 grams or 1.27 ounces.

In length that puts it in between, for sake of example, a Benchmade Model 32 and 51. It’s about the same overall length when open as a 32, actually, owing to the longer handles but shorter blade assembly.

I also did a trainer version of the blade, presented here in eye-searing green for safety. This is for practice, or can be used by any prospective waddlers who happen to live someplace with insufficient Freedomtm where live blade balisongs may be illegal.

And I did a better job of it than that damn carrot. At least I can say that for myself.

The Rockhopper is pretty much exactly as complicated on the inside as a Morpho, as well. A full build requires 27 individual components, all of which you get the fun an excitement of assembling to get to the finished product. Once again, I’m not going to detail the assembly process – which is rather involved – for the sake of brevity. That’s all detailed on my Printables post.

Want one? Of course you do. Get the files here.