I’ve printed similar objects with a different colored PLA, but I ran out of it and switched to this.

Is it possible that this could be influencing the outcome?

I have tried reducing the printing speed by 50%, but this did not seem to have a significant impact.

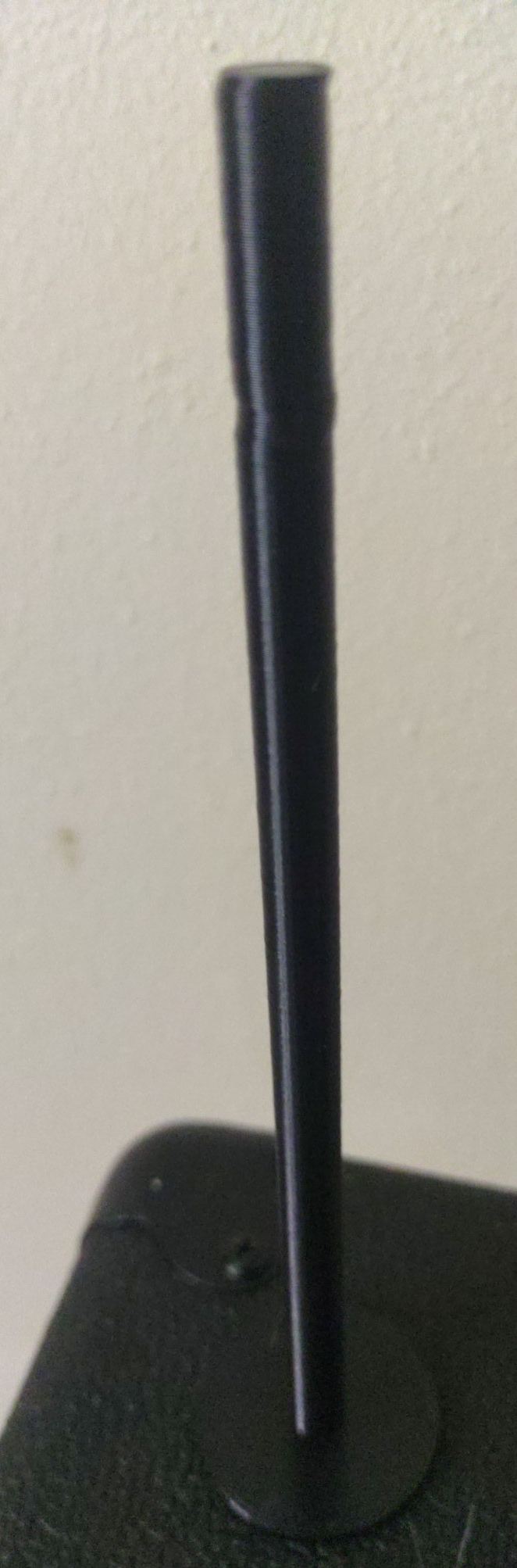

[SOLUTION] The problem was a loose screw. The offending part as well as the new result are pictured below. It’s not perfect, which I guess is actually a part of the model this time, but it’s good enough for my purposes and way better than what it was before.

I figured this out by twisting the Z-axis thingy manually all the way to the top to see if I could feel any issues. Towards the top, it would start to ‘skip’, where I would turn and pretty much nothing would happen. I assume this has to do with the lack of lube at the top because my prints rarely go that high. I checked to see if the screws were loose, and sure enough, the top one was. I tightened it up and now my printer is printing like the beast I remember!

Check if your print is wobbling when it reaches that height. If it does, you may need to add support to fix that - a few organic support touch points halfway up should help

Could you give me advice on how to do that? Is it something that I would have to add manually in a 3D modeling program, or is there a way to do it in Cura?

I am not too familiar with Cura, but I don’t think they have the ‘support painting’ feature of prusaslicer and the likes that would allow this. In those, you can paint where you’d like your support to touch or use modifier meshes to selectively add regions that should be supported. It’s the easiest way I know, though I have heard that Meshmixer also used to be able to do that… but I’ve never tried.