I feel like the garnet I cut first lulled me into a false sense of security. I did myself no favors picking a more complex cut, either. Quartz is ANNOYING!

The video mercifully does not show it, but my meetpoints are absolute trash on this stone. I used way too much force and popped it off the dop when polishing my pavilion, so my girdle and my crown don’t quite align either.

I struggled heavily with the prepolish step, which in turn led to my polish taking ages. I’m currently using a Zinc+ with 8k Pandimonium which was dreamy on my garnet but the quartz was less enthusiastic about it. Am I just underestimating quartz? What do you guys use for prepolishing?

Quartz is definitely a bastard. The only thing that helped me was getting hold of a couple of lightning laps - https://lightninglap.com/ - the 3k resin bonded lap polishes like an 8k, and then a CeOx resin polishing lap from them.

I’ve never figured out how to get a satisfying polish with anything I have to apply to a lap, it just becomes scratch city.

Stone looks lovely though!

Thank you! I think I will try the Lightning Lap 3k, general consensus from everyone here is that 3k makes a difference.

I will say that the CeOx on Darkside is quite good, but it can’t totally make up for a shit prepolish. If I can set it up for success with a better prepolish I think I’ll be much happier with my process. Hopefully LL saves the day!

I’ve been so impressed with the LL pads that, outside of bonded cutting disks, I don’t use anything else. Your milage may vary, though!

In my experience, quartz requires patience due to the hardness. It cuts slow and you will find yourself using more force than you need to resulting in popping the stone off of the dop. I can’t tell you how many times I’ve done exactly that… even these days knowing better I still do.

When I do quartz, mostly amethyst these days, I use a REALLY old crystalite 3k aluminum lap. This thing is at least 30 years old and still prepolishes nicely. With quartz I almost get a polish on the facets. I’ve tried the newer versions of this lap, and they are complete trash, as they have an imperfect surface which causes deep scratches on the surface you are trying to prepolish. I’m going to have to get a new pre-polish lap soonish as I can tell that my trusty 3k is nearing the end of its life. 😔

For polish I use 60k diamond on a Batt.

Thanks for the advice! It seems the overwhelming theme here is I need a nice 3k lap. I might try Lightnings Laps to see how they do.

I know I’m nowhere near this point, but how does an end-of-life lap behave? Does it just polish slower, or start to polish unevenly, or…?

From my own experience, it’s the prepolish to polish step that give so much trouble with quartz. I usually get around this by doing a very clean 3k grit pre-polishand then go straight to polishing. Ideally I’d like to use a good 8k prepolish but with quartz being so finicky in regards to contamination and scratching, I get better results without it.

If I want to do quartz right, and get clean flat razor-sharp facets, this is what I do. I have an old solid steel crystalite lap that is 3k Diamond and pretty worn. Does an excellent prepolish. Then I go straight to 50k Diamond powder on a gear loose BA5T lap. For the best way to charge the lap, I’d watch videos on how Roger Dery does it. It’s basically the same technique I use and it works every time, albeit it’s expensive.

If you want a way that’s quick, cheap, and VERY easy, go directly from 3000 grit (steel topper lap works fine here) pre-polish to a cerium oxide Mylar pad (spectra or similar). Mylar pads are known for facet rounding but you can minimized this a great deal with very light pressure.

Good luck!

Oh man, I could use some good videos on how to charge laps, I am so concerned I’m probably overdoing it when I do mine. I will check him out!

Universal consensus is that I need a 3k lap, so I guess I’ll be buying one soon! Thanks for the advice! 🙏

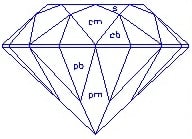

I forgot to note: this is a rutilated quartz, design is Oval 133 by Jeff Graham.