Quick google search shows that China has its own Quartz mines, so I’m not sure if those are unsuitable for certain semiconductors or if the use of “world” here just means

More like

I have empathy for the human lives lost to flooding, but as for the disruption of the Yankkkee reich’s quartz mines for the “world’s” semiconductor industry specifically, I can only see that as a good thing.

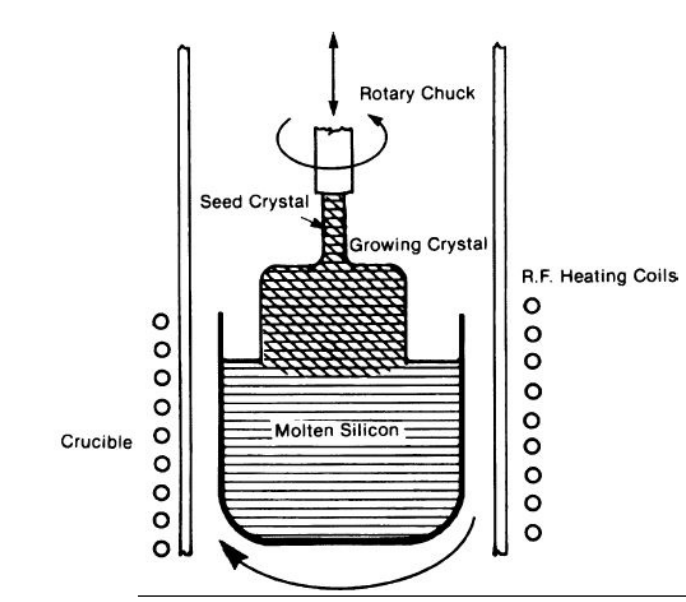

here’s some background information and speculation, as someone not involved in the industy. the silicon wafers used for making chips are big single crystals, which are made by the Czochralski method

the crucible is also made of silica and needs to be very perfect, so that no crystals are seeded from the walls, so it makes sense to me that the crucible needs to be at least the purity of the desired silicon wafers - which is at least 99.9999% pure and for research-grade samples 99.99999999% pure. I suspect that the leading-edge nodes requires the high-end of this scale. Its economical to start with the highest purity material that you can, which according to Conway’s Material World comes from spruce pine, but its possible to use a lower grade starting material.

the crucible is also made of silica and needs to be very perfect, so that no crystals are seeded from the walls, so it makes sense to me that the crucible needs to be at least the purity of the desired silicon wafers - which is at least 99.9999% pure and for research-grade samples 99.99999999% pure. I suspect that the leading-edge nodes requires the high-end of this scale. Its economical to start with the highest purity material that you can, which according to Conway’s Material World comes from spruce pine, but its possible to use a lower grade starting material.High purity quartz has been identified as a strategic resource so a number of countries have started exploring sites or subsiding this sort of quartz mining - Russia, China, Australia and a few others

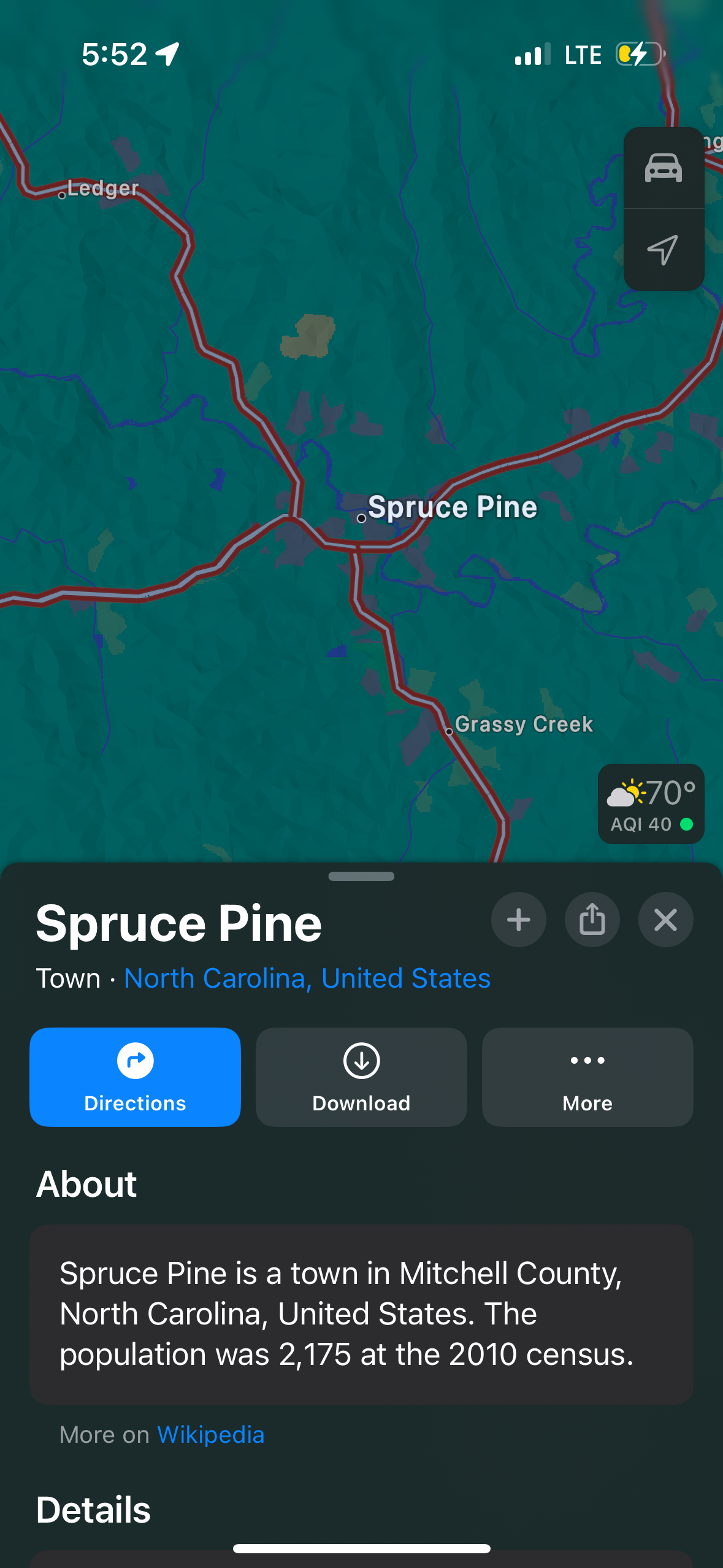

Just looking at Apple Maps you can tell shit ain’t good

Ain’t got no roads left

this pic is too damn small

Spruce Pine is fucked right now, eye of the hurricane went right over. National Guard is already there though so they will be receiving aid sooner than other communities.

i am like baby when it comes to tech manufacturing but i do happen to be aware that quartz is an exceedingly common rock, so what on earth is this about

like do semiconductors need literal tons of quartz? very specific kinds of quartz? this is genuinely baffling

It is very pure. You can use any quartz, but then you have to purify it first, and it is expensive.

really? you have to do that for like, everything you mine. does this NC one just have such an amazing deposit that it makes other options uneconomical?

Kinda? Western NC has been a mining hub for forever and they aren’t short on quartz at all. You could do it other places but I imagine the startup costs and the relatively poor margins on that kind of manufacturing make it unattractive, at least in America.

From the article, seems like it was due to unique geological properties.

Geologically speaking, the uniquely pure minerals at Spruce Mine were created about 380 million years ago when Africa collided with North America. This momentous collision, however slow, caused intense friction and heat miles below the Earth’s surface. According to Sibelco, the Spruce Mine minerals were created by a rich mineral-forming liquid that cooled and crystallized over time. A standout feature of these minerals is that they were made in their purest forms due to a lack of water, which caused all the friction.

It does later say that similarly high purity can be reached with synthetic quartz but that it would take time to scale up that industry.

Quartz is pretty common as a digital oscillator but it’s possible to use other methods. Certain iPhones used a different oscillator that are sensitive to atmospheric Helium.

Not sure where else in the supply chain it’s needed, and how easily it is to swap quartz oscillators for other components in existing designs.

digital oscillator

i have no idea what an oscillator gizmo entails

Your computer’s chips all have a clock rate, which controls how fast these circuits switches from positive to negative voltages. These clock rates are synchronised using an oscillator, often made of quartz.

By driving the clock rates from a single oscillator, multiple components can have different speeds but can stay in sync with each other, which is how we can transfer data from different components seamlessly.

An oscillator’s output goes up and down. They can be sine waves (called harmonic oscillators), or any kind of wave. The ones used in digital circuitry make square waves.

MEMS are also made of silicon.

quartz oscillators were basically the first MEMS.(i wrote that but actually its not true lol. something else cool is saw filters which kind of build on the concept of quartz oscillators btw) cool fact: the reason helium kills MEMS is because the atoms are so small that they can diffuse their way through the wall of the device, filling it up with helium and the air resistance then stops it from working!deleted by creator

Don’t post let’s blow it up. Don’t post let’s blow it up

I’m not really sure you need to lol seems like the hurricane might’ve done it for you

Yeah well I did have countless people tell me when I was younger that I was over blowing the effects of climate change. Also one of our politicians did just insist that we wouldn’t stop driving cars because we are a car driving country. So I’m gonna lol as this country collapses because I’ve spent 16 years here and was treated like a lunatic when I spoke about stuff like this.

“Nothing ever happens” smuglords keep collecting those Ls.

The facility is okay. The roads are gone. I think it’s behind used as a distribution and evac site currently.